In fast-paced manufacturing environments, spills aren’t just messes, they’re hazards. Whether it’s oil, chemicals, coolants, or water, leaks and spills can lead to safety risks, equipment damage, or regulatory noncompliance. That’s why many savvy operations managers rely on sorbent rolls as a preventive barrier, not just for cleanup, but for protection.

At Absorbents Online, we know that preventing spills is far more efficient than reacting to them. In this post, we’ll break down what sorbent rolls are, how they function as protective barriers in manufacturing, and why they’re a smart investment for your facility.

Entities and Their Relationships

Sorbent Rolls

- Attributes: Absorbent mats on a roll; made from polypropylene or natural fibers; available in oil-only, universal, and chemical versions.

- Function: Absorb and contain liquids before they spread; used to create barriers or pathways for spill control.

Manufacturing Environments

- Attributes: High-activity areas; exposure to machinery, chemicals, lubricants, and foot traffic.

- Needs: Spill prevention, safety, OSHA compliance, equipment protection.

Spill Containment

- Attributes: Regulatory requirement; includes barriers, berms, pallets, mats, and absorbents.

- Relation to Sorbent Rolls: Sorbent rolls serve as part of a broader spill containment system.

Absorbents Online

- Attributes: Online supplier of spill containment products; offers variety, bulk pricing, and quick shipping.

- Relation to Manufacturing: Source for sorbent rolls and other spill control products tailored to industrial needs.

Why Spill Prevention Matters in Manufacturing

Manufacturing floors are filled with potential spill sources: leaky drums, splashes from filling stations, or condensation from equipment. Left unchecked, even minor drips can escalate into safety incidents or cause slip-and-fall accidents. These spills can also contaminate other materials or machinery, leading to downtime and costly cleanups.

Preventive spill containment is not just smart, it’s often required. OSHA, EPA, and local environmental agencies all have guidelines mandating spill preparedness, especially when dealing with oils and hazardous chemicals. That’s where sorbent rolls come in.

What Are Sorbent Rolls?

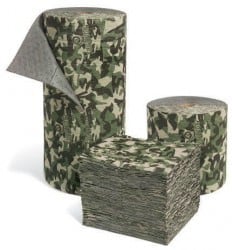

Sorbent rolls are absorbent mats sold in roll form. Think of them like giant, ultra-durable paper towels made for industrial settings. They come in different sizes, thicknesses, and absorbency levels, and are available for:

- Universal use (for water, oil, coolants)

- Oil-only spills (repels water, absorbs hydrocarbons)

- Hazmat/chemical applications (for aggressive acids, bases, solvents)

Because of their flexibility and size, they can be rolled out to cover large areas, cut to fit tight spaces, or layered for added absorbency.

How Sorbent Rolls Work as a Preventive Barrier

Unlike absorbent pads or pillows that are typically used after a spill has occurred, sorbent rolls shine in proactive containment. Here are some common use cases in manufacturing facilities:

1. Lining Walkways and Aisles

Manufacturing floors often see drips and spills near production lines. Placing sorbent rolls along walkways ensures liquids are absorbed before they become hazards. Plus, they reduce slip risks while keeping the floor visibly cleaner.

2. Surrounding Machinery

Machines that use oils or coolants often experience leaks or overspray. By creating a perimeter barrier with a sorbent roll, you can contain any liquid within a safe, controlled area, preventing it from spreading.

3. Under Pallets and Storage Racks

Leaky drums or containers are a nightmare if left unchecked. Laying sorbent roll sheets under pallets or along the base of shelving units adds a layer of security against unknown or slow leaks.

4. Temporary Spill Containment Zones

During maintenance or refueling tasks, rolls can be quickly deployed to surround a work zone. They’re easy to roll out and dispose of after use, making them perfect for high-mobility operations.

5. Doorway or Threshold Protection

Liquids can migrate from one room to another, especially through foot or forklift traffic. Laying down a roll at the base of a doorway acts like a sponge gate, stopping spill migration.

Benefits of Sorbent Rolls in Manufacturing

Cost-Effective Protection

Using sorbent rolls as a barrier means fewer expensive cleanups, reduced downtime, and less labor spent managing emergencies.

Easy to Deploy and Customize

With perforated sections or customizable lengths, you can cut the right size roll for each application, no waste.

Improved Workplace Safety

Slip-resistant backings and high-absorbency materials keep floors dry and reduce injury risks.

OSHA & EPA Compliance

Preventing spills helps meet local and federal regulations on spill containment and stormwater pollution.

Cleaner Work Environment

Preventive barriers mean your facility stays clean and professional-looking, even under heavy use.

How to Choose the Right Sorbent Roll

When selecting sorbent rolls for your facility, consider:

- Type of liquids present: Use oil-only rolls for hydrocarbons, universal rolls for mixed liquids, and chemical sorbents for aggressive materials.

- Size of coverage area: Rolls come in widths from 15” to 58”, and lengths from 50’ to 300’.

- Durability needs: For high-traffic zones, look for dimpled or bonded rolls with extra strength.

- Disposal requirements: Always follow proper disposal guidelines based on the liquids absorbed.

If you’re unsure which type to use, the experts at Absorbents Online are ready to help match your needs with the perfect solution.

Real-World Example: Stopping Downtime with Sorbent Rolls

A Midwest auto parts manufacturer had frequent spills from their CNC machines. Coolant and lubricant leaks would spread across the floor, creating hazards and requiring shutdowns for cleaning. After installing universal sorbent rolls around the base of their machinery, they saw a 60% reduction in cleanup time and zero slip incidents in six months.

The result? Less downtime, improved morale, and fewer headaches for safety managers. It’s a simple fix with big ROI.

More Than Just Rolls: Build Your Spill Containment Strategy

Sorbent rolls are a powerful tool, but they’re even more effective when paired with a complete spill prevention program. That might include:

- Spill containment pallets for drums

- Spill kits for quick responses

- Drain covers to prevent sewer contamination

- Secondary containment berms for mobile equipment

Absorbents Online offers everything you need to build a custom containment strategy for your manufacturing operation.

Final Thoughts

In manufacturing, it’s not a question of if a spill will happen, it’s when. By integrating sorbent rolls as a preventive barrier, you take control of your work environment, reduce risk, and save money over the long term.

They’re cost-effective, easy to use, and make regulatory compliance much easier. Whether you’re dealing with oils, chemicals, or everyday spills, a roll can be the barrier that keeps your operation running smoothly.

Shop Smart. Stay Safe.

At Absorbents Online, we’ve been helping manufacturers like you stay safe and compliant for over 20 years. Our high-quality sorbent rolls and spill containment solutions are just a click away.👉 Shop Sorbent Rolls Now and build your spill barrier strategy today.