Unlock the Power of Wringers for Absorbents in Your Workplace

Picture this: You just had a little accident in your workplace, and unexpectedly spilled a container of fluid. You’ve diligently followed safety procedures, and reached for your trusty sorbent mat, towel, or rag to deal with the mess. However, after cleaning the spill up, there’s a lingering feeling that you’ve lost a valuable resource that could have been put to better use. Is it truly impossible to recover the fluid you’ve just spilled?

No matter how careful you are, accidents are an inevitable part of any workplace. Spills are not only hazardous but also result in the wastage of precious resources. Fortunately, there’s a solution that can help you recover a significant portion of the spilled fluid and save your business money in the process. Enter wringers for absorbents – your secret weapon against wasteful spills.

The Business Benefits of Using Wringers for Absorbents

Did you know that wringers for absorbents can recover up to 90% of absorbed fluids from most sorbent mats, towels, or rags? That elevates wringers as one of the true unsung heroes of the workplace. When paired with reusable absorbent pads, a wringer can greatly reduce spill costs and chemical fluid waste for your facility.

- Cost Savings: According to a 1993 project by the U.S. Environmental Protection Agency (EPA), using a wringer could save a company 51 to 75% a year—mainly by reducing sorbent pad disposal costs. Furthermore, the initial investment in a wringer can pay for itself in a remarkably short span; typically within 2.8 to 5 weeks!

- Environmental Responsibility: By recovering and reusing absorbed fluids, you contribute to a greener and more sustainable workplace. This not only aligns with modern environmental standards but also enhances your company’s reputation as a responsible corporate citizen.

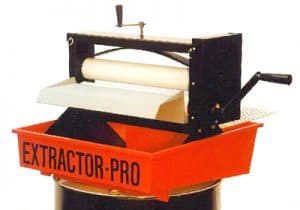

Introducing the Pro Model Wringer

Our heavy-duty wringer has 19-inch rollers capable of accommodating 18-inch absorbent pads without any need for folding. Thanks to its adjustable chemical resistant rollers, you can also use it to wring out up to four 3-inch absorbent socks, as well as absorbent booms. The all-steel frame is rust-proof, and you can mount this wringer to a closed-head 55-gallon drum for easy fluid collection. A built–in anti–spill/fluid indicator valve warns you when a five-gallon capacity remains in drum.

For added convenience, we offer an optional hands-free electric motor drive for this model. At AbsorbentsOnline, we understand that different workplaces have unique requirements, so we can provide the wringer with custom extractor widths and voltages to suit your specialized needs.

Squeeze Extra Performance Out of Your Absorbents: Order Your Wringer Today!

The next time you face a fluid spill in your facility, there’s no need to panic. Instead, reach for a wringer – a solution that benefits both the environment and your bottom line.

AbsorbentsOnline is here to assist you every step of the way. Don’t hesitate to contact us via email or give us a call toll-free at (800) 869-9633. With wringers for absorbents, you’ll be well-equipped to tackle spills efficiently, responsibly, and cost-effectively.

This is a revision to a blog post with an original publication date of December 17, 2014.

The Environmental Protection Agency (EPA) recently proposed new changes to the country’s Agricultural Worker Protection Standard (WPS) in an effort to reduce agricultural workers’ exposure to toxic pesticides. There are around a dozen specific changes introduced, all of which are designed to protect farmers and other agricultural workers who handle pesticide-covered products on a daily basis.

The Environmental Protection Agency (EPA) recently proposed new changes to the country’s Agricultural Worker Protection Standard (WPS) in an effort to reduce agricultural workers’ exposure to toxic pesticides. There are around a dozen specific changes introduced, all of which are designed to protect farmers and other agricultural workers who handle pesticide-covered products on a daily basis. On Monday, officials with the Environmental Protection Agency (EPA) announced a new rule that would place restrictions on

On Monday, officials with the Environmental Protection Agency (EPA) announced a new rule that would place restrictions on  Last month, the Environmental Protection Agency (EPA) published a new rule which would limit the carbon pollution of new coal-burning power plants. EPA Administrator Gina McCarthy announced the proposed rule in Q4, 2013. However, it took officials several months to finalize the rule before making it available to the public. You can now access and view the new carbon emission rule proposed by the EPA at

Last month, the Environmental Protection Agency (EPA) published a new rule which would limit the carbon pollution of new coal-burning power plants. EPA Administrator Gina McCarthy announced the proposed rule in Q4, 2013. However, it took officials several months to finalize the rule before making it available to the public. You can now access and view the new carbon emission rule proposed by the EPA at  Earlier this month, the U.S. Environmental Protection Agency released tons of new data found in roughly 1,800 chemicals. These chemicals are used in everything from processed foods to laundry detergents, skincare products, and even over-the-counter drugs. The EPA’s goal in screening the 1,800 everyday consumer chemicals is to predict health concerns and risks associated with common household products.

Earlier this month, the U.S. Environmental Protection Agency released tons of new data found in roughly 1,800 chemicals. These chemicals are used in everything from processed foods to laundry detergents, skincare products, and even over-the-counter drugs. The EPA’s goal in screening the 1,800 everyday consumer chemicals is to predict health concerns and risks associated with common household products.

Companies can benefit from performing internal environmental audits in several different ways. Instead of waiting around for the Environmental Protection Agency (EPA) to investigate, owners should take the initiative to conduct their own internal audits. By which we mean checking for any and all environmental violations and issues. For example, non-compliance with environmental regulations for emissions or wastewater discharge.

Companies can benefit from performing internal environmental audits in several different ways. Instead of waiting around for the Environmental Protection Agency (EPA) to investigate, owners should take the initiative to conduct their own internal audits. By which we mean checking for any and all environmental violations and issues. For example, non-compliance with environmental regulations for emissions or wastewater discharge. Need help with environmental management systems or supplies for your business? Contact Travis Zdrazil at

Need help with environmental management systems or supplies for your business? Contact Travis Zdrazil at