Oil spills are catastrophic events that can have long-lasting impacts on the environment. While many people are familiar with oil spills in oceans and seas, the impact on rivers and streams is equally concerning. These freshwater bodies are vital to ecosystems, local communities, and industries. In this article, we will explore the environmental impact of oil spills on rivers and streams, focusing on habitat destruction, ecological restoration, and mitigation measures like oil spill booms.

Understanding the Basics of Oil Spills

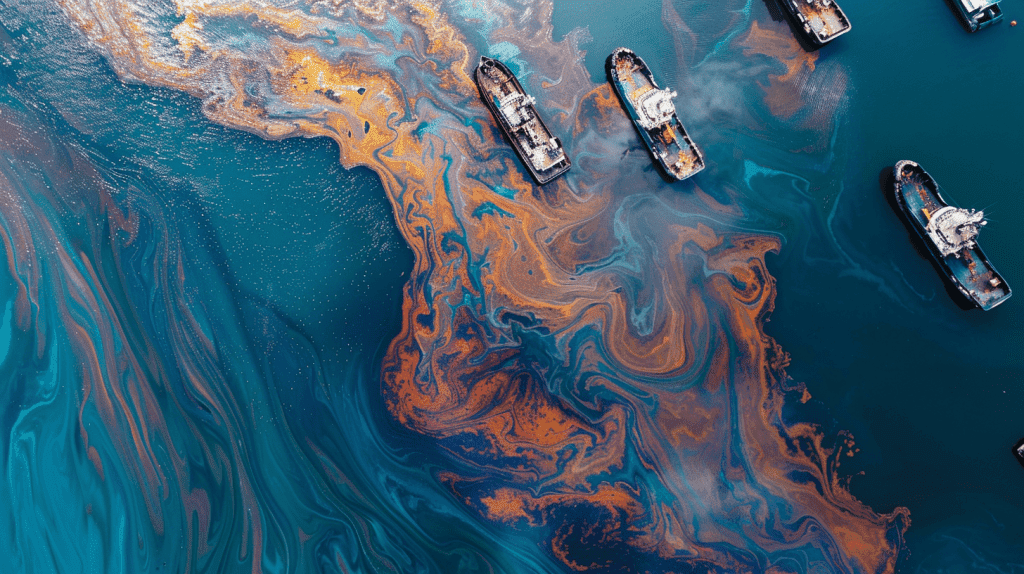

Oil spills occur when liquid petroleum hydrocarbons are released into the environment, typically due to accidents or human error. These spills can originate from various sources, including pipelines, ships, or offshore rigs. When oil enters a river or stream, it spreads quickly, affecting water quality and the organisms living in and around the water.

Causes and Sources of Oil Spills

Oil spills in freshwater bodies can result from numerous sources. Pipeline leaks are a common cause, often due to corrosion or mechanical failures. Shipping accidents, including collisions or groundings, can lead to significant spills, especially when tankers are involved. Additionally, human errors during the transfer of oil between vessels or facilities can result in accidental discharges.

Oil Behavior in Freshwater vs. Saltwater

The behavior of oil differs significantly between freshwater and saltwater environments. In freshwater, oil tends to spread more rapidly and form a thinner layer due to the lower density and viscosity compared to seawater. This rapid spread can make containment more challenging, requiring immediate response efforts to limit environmental damage.

Immediate Environmental Effects

The immediate effects of an oil spill are visible and devastating. Oil creates a slick on the water’s surface, which can spread over vast areas in a short time. This slick disrupts the natural surface tension of water, affecting everything from waterfowl that rely on buoyancy to insects that skate across the surface. The visual impact is often matched by a strong, pervasive odor that affects both wildlife and humans.

The Environmental Impact of Oil Spills

Habitat Destruction

One of the most immediate consequences of an oil spill is habitat destruction. Rivers and streams support a wide variety of plant and animal life, and an oil spill can severely damage these ecosystems. The oil can coat the surfaces of plants, reducing their ability to photosynthesize and grow. Aquatic animals, such as fish and amphibians, can be poisoned by ingesting oil or by absorbing it through their skin. This can lead to a decline in population numbers and disrupt the food chain, affecting predators that rely on these species for sustenance.

Impact on Aquatic Vegetation

Aquatic vegetation suffers greatly when oil coats its surfaces, as it blocks sunlight necessary for photosynthesis. This blockage leads to a significant reduction in energy production for plants, stunting growth and potentially causing plant death. The loss of vegetation can destabilize riverbanks, leading to increased erosion and loss of habitat for other organisms.

Effects on Fish and Amphibians

Fish and amphibians are particularly vulnerable to oil spills. Exposure to oil can cause acute toxicity, leading to immediate mortality in severe cases. Sub-lethal effects include impaired growth and reproduction, making populations less resilient over time. Amphibians, which absorb substances through their permeable skin, are especially at risk, as even small amounts of oil can be lethal.

Disruption of the Food Chain

Oil spills can have cascading effects throughout the food chain. When primary producers like algae and aquatic plants decline, it affects herbivores that feed on them, such as small fish and invertebrates. This, in turn, impacts predators that rely on these animals for food. Over time, entire ecosystems can be altered, with some species potentially disappearing altogether.

Water Quality Degradation

Oil spills have a profound impact on water quality. The presence of oil in water bodies increases toxicity levels, making the water unsafe for consumption by humans and animals. It can also lead to oxygen depletion, as oil reduces the amount of light penetrating the water and hinders the process of photosynthesis. This reduction in oxygen levels can cause fish kills and negatively affect aquatic life that depends on oxygenated water.

Increased Toxicity Levels

Oil introduces a range of toxic compounds into the water, including polycyclic aromatic hydrocarbons (PAHs) and heavy metals. These substances can persist in the environment, posing long-term health risks to both aquatic life and humans. Consuming contaminated water or fish can lead to serious health issues, including cancer and developmental problems.

Oxygen Depletion and Fish Kills

The presence of oil on the water’s surface reduces oxygen exchange between the air and water. This can lead to hypoxia, a condition where dissolved oxygen levels drop to dangerously low levels. Fish and other aerobic organisms struggle to survive in such conditions, often resulting in mass die-offs that further disrupt ecological balance.

Impact on Drinking Water

Many communities rely on rivers and streams for their drinking water supply. Oil spills can contaminate these sources, making the water unsafe for human consumption without extensive treatment. This poses significant challenges for affected communities, requiring costly and time-consuming cleanup efforts to restore safe water supplies.

Long-Term Environmental Consequences

The effects of oil spills are not limited to immediate habitat destruction. Over time, the oil can penetrate sediments at the bottom of rivers and streams, leading to long-term contamination. This can affect organisms that live in or feed on these sediments and can take years, or even decades, to fully remediate. The long-term impact of oil spills can also be seen in reduced biodiversity, as some species may never fully recover or return to the affected areas.

Sediment Contamination

Oil can bind to particles in the water, eventually settling in sediments where it can persist for years. These contaminated sediments become a source of ongoing pollution, as they slowly release toxic compounds back into the water column. Benthic organisms, which live in or on the sediments, are directly affected, with potential impacts on their health and reproduction.

Biodiversity Loss

The long-term presence of oil in an ecosystem can lead to significant reductions in biodiversity. Some species may be more sensitive to oil pollution, leading to their decline or local extinction. This loss of biodiversity can alter community structures, making ecosystems less resilient to other environmental stresses and reducing the overall health of the ecosystem.

Recovery Challenges

Restoring ecosystems affected by oil spills is a complex process that can take decades. The resilience of the ecosystem, the severity of the spill, and the effectiveness of the response all influence recovery times. Some species may never fully recover, requiring ongoing conservation efforts to prevent further biodiversity loss and to support ecosystem health.

Ecological Restoration Efforts

Restoring ecosystems affected by oil spills is a challenging and lengthy process. Ecological restoration involves cleaning up the oil, rehabilitating affected wildlife, and restoring damaged habitats.

Cleanup and Remediation

The first step in ecological restoration is the cleanup and removal of oil from the affected area. This process can involve physical removal, such as skimming oil from the water’s surface, and chemical methods, like dispersants that break down oil into smaller particles. Bioremediation, which uses microorganisms to degrade oil, is another method used in restoration efforts.

Physical Cleanup Methods

Physical methods involve using equipment like skimmers and absorbent materials to remove oil from the water’s surface. These methods are often the first line of defense, as they can quickly reduce the volume of oil in the environment. However, they require rapid deployment and favorable weather conditions to be effective.

Chemical and Biological Techniques

Chemical dispersants can break oil into smaller droplets, enhancing natural degradation processes. While effective in certain conditions, they can also pose risks to aquatic life. Bioremediation leverages naturally occurring or introduced microorganisms to degrade oil into less harmful substances. This approach can be effective over the long term but requires careful monitoring and management.

Challenges in Oil Removal

Removing oil from freshwater environments presents unique challenges. The rapid spread of oil and the presence of vegetation and wildlife can complicate cleanup efforts. Additionally, access to affected areas may be limited, requiring specialized equipment and expertise to effectively address the contamination.

Wildlife Rehabilitation

Wildlife rehabilitation is an essential part of ecological restoration. Animals affected by oil spills need to be cleaned and cared for before they can be released back into the wild. This process involves removing oil from their bodies, providing medical treatment, and ensuring they are healthy enough to survive in their natural habitat.

Cleaning and Treating Affected Wildlife

The process of cleaning oil from wildlife is meticulous and labor-intensive. Specialists use gentle cleaning agents to remove oil from feathers and fur, ensuring that animals are not further harmed during the process. Medical treatment often follows, addressing any injuries or illnesses resulting from oil exposure.

Release and Monitoring

Once cleaned and rehabilitated, wildlife is typically released back into their natural habitats. However, this is not the end of the process. Continuous monitoring is essential to ensure that these animals successfully reintegrate into the wild and that their health remains stable over time.

The Role of Rescue Centers

Rescue centers play a crucial role in wildlife rehabilitation during oil spills. These facilities are equipped to handle large numbers of affected animals, providing care and treatment until they can be released. Collaboration between rescue centers, government agencies, and environmental organizations is vital for effective wildlife response efforts.

Habitat Restoration

Restoring the habitat itself is a crucial step in the ecological restoration process. This can involve replanting vegetation, stabilizing shorelines, and monitoring water quality to ensure that conditions return to normal. Restoration efforts require collaboration between government agencies, environmental organizations, and local communities.

Replanting and Vegetation Recovery

Replanting native vegetation is critical for restoring habitat structure and function. Native plants help stabilize soil, prevent erosion, and provide habitat for wildlife. These efforts often require careful planning and community involvement to ensure the successful re-establishment of vegetation.

Shoreline Stabilization

Stabilizing shorelines prevents further erosion and habitat loss. Techniques may include planting vegetation, using biodegradable structures, or employing engineering solutions like rock revetments. These measures help protect the riverbank while providing habitat for aquatic and terrestrial species.

Water Quality Monitoring

Continuous water quality monitoring is essential to track recovery progress. By measuring parameters such as dissolved oxygen, pH, and contaminant levels, restoration teams can assess the effectiveness of their efforts and make necessary adjustments. This ongoing monitoring ensures that ecosystems are on a path to recovery and helps prevent future incidents.

Mitigation Measures: The Role of Oil Spill Booms

Preventing oil spills and minimizing their impact when they occur is vital. One of the most effective tools used in oil spill response is the oil spill boom. These barriers float on the water’s surface and help contain the spread of oil, making it easier to remove.

Types of Oil Spill Booms

There are various types of oil spill booms designed for different conditions. Some are used in calm waters, while others are designed to withstand strong currents and waves. Selecting the appropriate boom is critical to effectively containing the oil and protecting the environment.

Calm Water Booms

Calm water booms are typically lightweight and easy to deploy, making them ideal for small spills in sheltered environments. They are not designed to handle rough conditions but can be very effective in calm rivers and streams where rapid response is possible.

Offshore and High Current Booms

For spills in more challenging conditions, robust booms capable of withstanding waves and strong currents are necessary. These booms are heavier and more durable, often featuring additional support systems to maintain their position in adverse weather.

Specialized Booms

In addition to standard booms, specialized designs exist for particular situations. Fire-resistant booms, for example, are used when there’s a risk of oil igniting. Ice booms are designed for cold environments where ice floes can complicate containment efforts. Selecting the right boom type is crucial for effective spill management.

Deployment and Effectiveness

Deploying oil spill booms requires strategic planning and coordination. Responders must quickly identify the spill location and deploy the booms to prevent the oil from spreading further. While booms are effective in containing oil, their success largely depends on factors such as weather conditions, the type of oil, and the speed of response.

Strategic Planning and Coordination

Effective boom deployment begins with thorough planning. Responders must consider the spill’s location, the type of oil, and environmental conditions to devise an effective strategy. Coordination between agencies and organizations ensures resources are used efficiently and response efforts are maximized.

Factors Affecting Boom Performance

Several factors influence the success of boom deployment. Weather conditions, such as wind and waves, can affect boom stability and containment efficiency. The type of oil is also crucial, as lighter oils spread more quickly, requiring rapid response to contain them effectively.

Limitations and Challenges

While booms are a vital tool in oil spill response, they have limitations. They are not effective in every situation, especially in high winds or rough seas. Additionally, booms require regular maintenance and monitoring to ensure they remain effective over time. Understanding these limitations is essential for developing comprehensive spill response strategies.

Conclusion

Oil spills in rivers and streams are devastating events that have significant environmental impacts. They lead to habitat destruction, water quality degradation, and long-term ecological consequences. However, through effective ecological restoration and mitigation measures like oil spill booms, it is possible to minimize these impacts and restore affected ecosystems. It is crucial for industries, governments, and communities to work together in preventing oil spills and responding swiftly when they occur, to protect our valuable freshwater resources.

Collaborative Efforts

The success of oil spill prevention and response efforts relies on collaboration. Governments, industries, and environmental organizations must work together to implement effective measures and respond rapidly to incidents. Community involvement is also critical, as local knowledge and resources can enhance response efforts and support restoration.

Prevention and Preparedness

Preventing oil spills requires investment in infrastructure, technology, and training. Regular inspections and maintenance of pipelines and vessels, along with the development of advanced monitoring systems, can reduce the risk of spills. Preparedness through training and simulations ensures that responders are ready to act quickly and effectively in the event of a spill.

The Path Forward

As we look to the future, it is essential to continue developing innovative solutions to prevent and mitigate oil spills. Research into new technologies, such as improved spill detection systems and more effective cleanup methods, will play a vital role in protecting our freshwater ecosystems. By prioritizing prevention and fostering collaboration, we can safeguard these vital resources for future generations.

Take Action: Shop at Absorbents Online for Oil Absorbent Booms

Protect our precious freshwater ecosystems by investing in high-quality oil absorbent booms from Absorbents Online. Our range of effective and specialized booms is designed to help you respond swiftly and efficiently to oil spills, ensuring minimal environmental impact. Don’t wait for a spill to happen—be prepared! Visit https://www.absorbentsonline.com today to explore our selection and safeguard your waterways.