Understanding the importance and types of chemical absorbents

If your company deals with the production, processing, storage, or handling of chemicals, you need appropriate absorbents readily available to maintain a safe and compliant workplace.

Chemical spills can occur unexpectedly, so having the right absorbents on hand allows you to effectively contain and clean the chemicals in a timely manner.

But with so many different types of spill absorbents available—differing in size, material, shape, and construction—how do you know which ones to choose? In this post, we break down the different types of chemical absorbents to help you make an informed choice.

Categorizing Absorbents

Absorbents are typically classified into three main categories:

- Universal – Universal absorbents are probably the most popular type of chemical absorbent and are gray in color. These versatile absorbents are designed to handle both oil-based and water-based chemical spills. The ability to effectively absorb various types of chemicals makes universal absorbents the preferred choice for most companies.

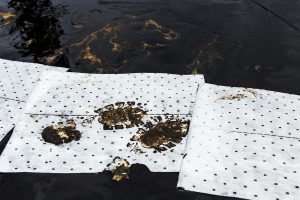

- Oil-Only – As the name suggests, white oil-only absorbents are specifically designed to tackle oil-based spills. If your company primarily deals with oil-based chemicals, opting for oil-only absorbents in the event of a spill is a sensible choice. Oil floats on top of water, making booms a common choice for containing oil spills. Oil-only absorbents repel water which means they float even after soaking up a hydrocarbon spill.

- Hazmat – The third category of chemical absorbent is yellow, and specifically formulated to handle aggressive chemicals that cannot be effectively absorbed by universal or oil-only absorbents. These absorbents are indispensable for managing spills involving hazardous materials. Moreover, you can also use hazmat absorbents for cleaning up water-based and oil-based chemical spills.

Different Types of Chemical Absorbents

Chemical absorbents come in various forms, each with its own unique purpose. For convenience, spill kits often contain a mix of these different options. We’ll delve into some examples, next.

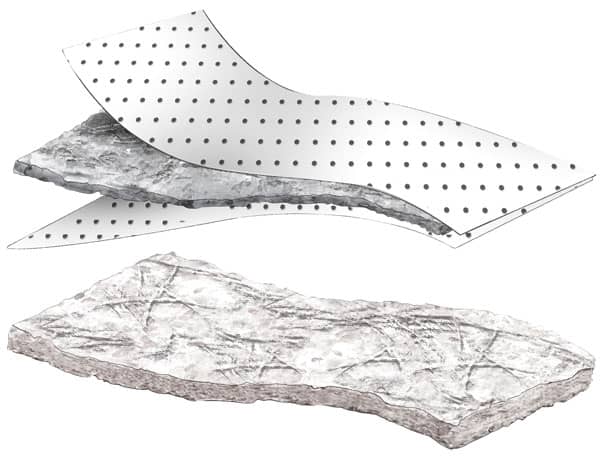

Pads, rolls, and mats

Absorbent pads are placed directly on top of a spill to soak up the chemical. Using pads designed for specific chemicals ensures optimal absorption. Some companies even use absorbent pads as a preventive measure by placing them beneath forklift storage areas, reducing the risk of oil spills on the floor.

Let’s not overlook the importance and convenience of basic absorbent rolls. These are essential for quickly wiping up small spills. Whenever a minor spill occurs, a few sheets of an absorbent roll can swiftly address the issue.

Booms, socks, and pillows

With their bulkier forms, booms, socks, and pillows represent another type of chemical absorbent product range. They’re typically utilized for larger spills that are difficult to contain with mats or pads alone. Socks and booms can enclose a chemical spill within a designated area while gradually absorbing and containing it. Then, pillows can be tossed into the center of the spill for additional absorbing power.

Benefits of Using Chemical Absorbents in the Workplace

Using chemical absorbents in the workplace offers several important benefits. Such as ensuring a safer environment for employees and helping companies meet federal compliance regulations. Let’s explore these advantages in detail:

- Enhanced Workplace Safety: The primary advantage of utilizing chemical absorbents is the significant enhancement in workplace safety. Chemical spills can lead to slip-and-fall accidents, fires, chemical exposures, and other hazardous situations. By having the appropriate absorbent materials readily available, companies can quickly respond to spills, contain them effectively, and minimize the potential risks to employees’ health and safety.

- Reduced Environmental Impact: Chemical spills can have detrimental effects on the environment if not properly managed. Absorbents play a crucial role in preventing the spread of chemicals and their subsequent contamination of soil, water sources, or nearby ecosystems. By using absorbents to promptly address spills, companies can minimize the negative impact on the environment and demonstrate their commitment to responsible environmental stewardship.

- Compliance with Occupational Safety and Health Administration (OSHA) and the Environmental Protection Agency (EPA) Regulations: Both OSHA and the EPA have established regulations and guidelines to ensure workplace safety and environmental protection. Using chemical absorbents aligns with these regulations, demonstrating compliance and a proactive approach to maintaining a safe and environmentally conscious workplace. By implementing proper spill control measures, companies can avoid potential penalties, fines, or legal consequences associated with non-compliance.

- Improved Operational Efficiency: Chemical spills can disrupt operations and lead to downtime while the cleanup process takes place. Having the right absorbents readily available allows for quicker containment and cleanup, minimizing the interruption to workflow and reducing potential financial losses. The ability to promptly address spills helps maintain operational efficiency and productivity.

- Cost Savings: The proactive use of chemical absorbents can also result in cost savings for companies. By promptly containing and cleaning up spills, potential damages to equipment, infrastructure, or inventory can be minimized or avoided altogether. Additionally, the reduction in workplace accidents and associated medical expenses, insurance claims, and legal costs contributes to overall cost savings for the company.

Final thoughts

In conclusion, the proper selection of chemical absorbents is crucial for maintaining a safe and compliant workplace. It is important to note that the specific requirements for chemical spill management and the choice of absorbents may vary depending on the industry and the types of chemicals involved. Understanding the different types of absorbents available and their specific uses will help you make informed decisions.

If you need advice on selecting chemical-compatible absorbents for your facility, reach out to AbsorbentsOnline. Our experts can help. Contact Travis Zdrazil at travis@absorbentsonline.com or (800) 869-9633.

This is a revision to a blog post with an original publication date of October 3, 2013

Stocking your warehouse with absorbents can be a daunting task if you’re not sure where to start.

Stocking your warehouse with absorbents can be a daunting task if you’re not sure where to start.

No matter what kind of facility you have, there are solutions for every spill and every site! This guide aims to help you determine which absorbents best suit your needs — but if you still aren’t sure, you can always get in touch with us. For questions, contact Travis Zdrazil at

No matter what kind of facility you have, there are solutions for every spill and every site! This guide aims to help you determine which absorbents best suit your needs — but if you still aren’t sure, you can always get in touch with us. For questions, contact Travis Zdrazil at

Spills left to advance and spread can cost contractors upwards of a hundred thousand dollars in site cleanup fees. That number doesn’t even include potential

Spills left to advance and spread can cost contractors upwards of a hundred thousand dollars in site cleanup fees. That number doesn’t even include potential

Most people in the workforce today don’t remember a time before OSHA. But nearly 50 years ago, there was no law saying any business leader had to provide a safe workplace for his or her employees.

Most people in the workforce today don’t remember a time before OSHA. But nearly 50 years ago, there was no law saying any business leader had to provide a safe workplace for his or her employees.